SERVICES

STEELGREEN uses the most modern cutting and molding technology for reinforcing rods, supported by a technical body whose experience, flexibility and capacity for innovation allowit to ensure the provision of a set of quality and rigorous services.

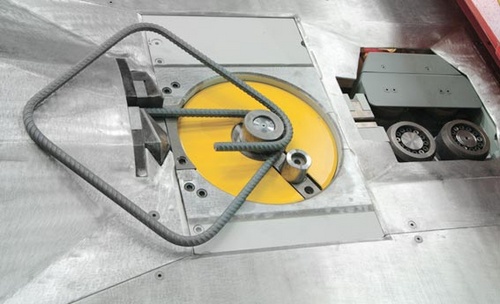

CUT TO MEASURE

We are able to perform simple cuts and special cuts with inclination, which can be defined degree by degree according to the specifications requested by the customer.

The service to cut ribbed bar to measure, normally with diameters 6, 8, 10, 12, 16, 20, 25, 32 and 40 mm in steel.

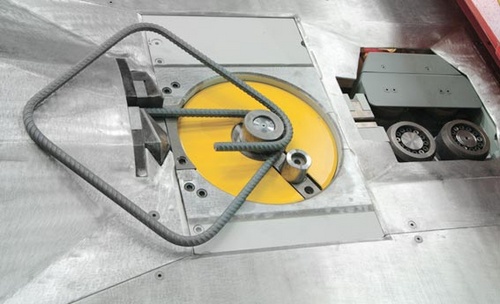

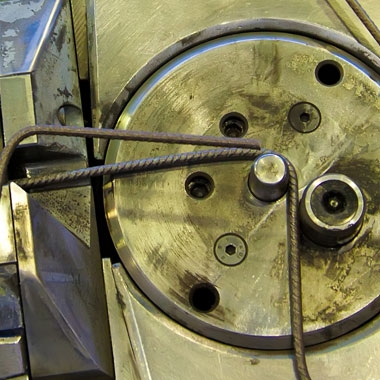

STRUCTURE MOLDING

The molding of structures normally specified by the designers is assembled with longitudinal and transversal bars that contribute to theresistance and bending efforts.

The stirrups are specifically bent according to customer drawings and molding plan.

PREPARATION

We have a specialized preparation team, they use the latest tools on the market to make customers completely satisfied with the reinforcements present in the project and identify in advance any possible errors and incompatibilities present in the execution drawings.

PRODUCTION OF CUTTINGS

Production of Electro-welded piles, through advanced machinery.

PLACEMENT ON SITE

STEELGREEN is specialized in on-site placement, having several years of experience and extensive knowledge in this area of work.

STEELGREEN for each work, proceeds with the analysis of the project, cut to measure, management of the construction process and molding,then proceeding to its assembly and application in the work, offering a “turnkey solution”.

Procedures for placing on site:

- Check the conformity of the reinforcement to be placed within the project;

- If necessary clean the reinforcements before being placed on site;

- Position and fix the reinforcement in place, placing separators with the appropriate distance to ensure the stipulated covering;

- Prepare the armor for the places where technical installations pass through.

PLANNING

- Meeting deadlines stipulated by the customer, through rigorous planning.